Description

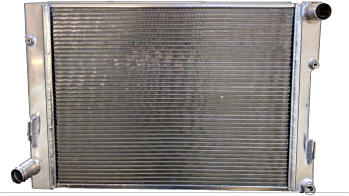

Direct drop-in easy fit! Fits just like the factory radiator!

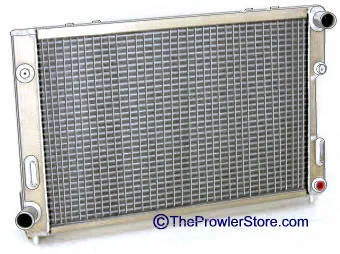

Prowler radiators are no longer available through Chrysler. No other company makes a drop-in radiator for the Prowler.

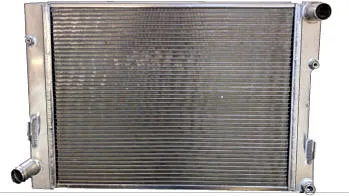

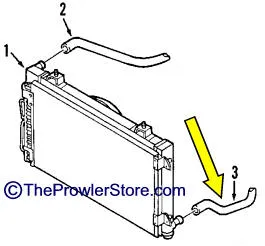

Ours is a super high-quality all-aluminum radiator with a direct drop-in fit. It includes a higher-capacity cooling reservoir for better heat extraction.

All aluminum and a direct fit with no modifications necessary.

High-quality radiator made specifically to fit and work on the Chrysler Plymouth Prowler.

- Drop-in fit for easy installation

- Engineered to exceed the manufacturer’s specifications

- Our radiators are designed to exceed original equipment standards

- All complete radiators are 100% leak-tested

- Highest grade all-aluminum materials are used to ensure product longevity

- Professionally welded construction – no screws, no plastic

- Made in America

Before you install your new radiator, check for electrolysis.

Test BEFORE you mount your new radiator

Testing for electrolysis in cooling systems

A voltmeter capable of reading both AC and DC currents is required to test cooling systems.

The meter must read from zero to the maximum voltage of the system in tenths of a volt. The leads must be long enough to reach between the coolant and the ground side of the battery.

An ohm function is also helpful to pinpoint areas of resistance in the electrical system that may cause current to ground through the coolant instead of the engineered circuit.

Procedure:

- Attach the proper meter lead to the ground side of the battery, negative-to-negative or positive-to-positive.

- Install the second lead into the coolant, touching only the coolant.

- Read DC and AC voltage with all systems off. If a block heater is present, also take a reading with it turned on. If an automatic battery charger is present, take a reading while it is running.

- Read DC and AC voltage with the starter engaged.

- Read DC and AC voltage with the engine running and all systems on: lights, coolers, fans, heaters, air conditioning, cell phone, two-way radio (both standby and transmit).

- This procedure will test the complete system except for the current generated by the rear transmission. With air bag suspensions, rubber pad suspensions, and rubber-mounted transmissions, current may travel up the drive shaft to ground through the coolant. Grounding rear ends and transmissions is strongly recommended.

- Voltage of 0 to 0.3 is normal in a cast-iron engine. 0.5 volts will destroy such an engine over time. Manufacturers report that just 0.15 volts will destroy an aluminum engine.

- The current will be AC if caused by static electricity.

- If the coolant shows electrical problems with all systems on, turn off one system at a time until the current stops. The last system turned off is causing the problem.

- Be especially careful with starters – they can damage the cooling system as much as an arc welder due to high amperage.

- Always replace the coolant if a current is detected. Electrical current destroys the protective chemicals in the coolant.

The following failures are not manufacturer defects and are not covered under warranty:

- Improper Flush – Cooling systems require a thorough flush of the radiator, engine, overflow tank, hoses, and heater core. Failure to do so will mix coolants and contaminants, creating a deadly cocktail for the cooling system.

- Corrosion – The correct coolant and distilled water mixture prescribed by the coolant manufacturer must be maintained. Water with high mineral content will create problems for aluminum radiators, not typically seen in copper radiators.

- Electrolysis – Electrolysis systematically removes the protective layer inside radiator tubes due to improper grounding. Grounding issues can result from poorly installed aftermarket accessories or incorrect collision repairs.